Low carbon transformation, Strategic Alliances

Become an outstanding supplier certified by major factories and build a semiconductor national team.

| Strategic Objectives | 2023 Goal | 2023 results and improvements | 2024 Goal |

|---|---|---|---|

| Environmental Sustainability | Participate in the Industrial Bureau's 2023 "Key Enterprise Smart Machinery Development Plan – Carbon Reduction Guidance Plan" and aim for an average annual electricity savings rate and carbon reduction benefit of over 5%. | Through collaboration with 10 supply chain partners, propose 44 energy improvement solutions, successfully reduce carbon emissions by 1,160 metric tons, save 2,280,191 kWh of electricity. | Introduce a digital carbon management platform, create a green supply chain, and guide 30 suppliers to achieve an annual electricity savings of 7 million kWh and carbon reduction of 3,500 tons. |

| Localization | Cultivate and integrate local high-end composite material supply chains, develop self-owned material supply lines, and strengthen material control and quality stability. | Promote supplier incoming quality improvement policy and add 207 exempted incoming materials. | Through the Co-Creation Innovation Platform, promote a localization alliance for semiconductors, foster core capabilities of key suppliers, and provide opportunities for local suppliers to enter the global semiconductor supply chain. |

| Quality | Improve the output and quality of Taiwan's EUV supply chain team, achieve high-precision processing product goals, and reach a 70% outsourcing target. Establish a project team for quality coaching, confirm the root cause analysis of quality defects and process improvements. | Establish a project team for quality coaching, confirm the root cause analysis of quality defects and process improvements, achieve a 70% outsourcing target for high-precision processing products, and coach the supply chain to adopt automated measurement techniques. | Through investments, acquisitions, strategic alliances, and technology collaborations with domestic companies, increase the market share of cooperative partners and achieve the goal of upgrading industry technology. |

Benefiting from the cultivation of a local supply chain by Taiwan's leading semiconductor factories, Gudeng Precision follows the same model, with the mission and vision of "Supporting Taiwan's Local Suppliers“

In 2023, Gudeng leveraged its supply chain influence to provide 15 supply chain partners with free courses, including RBA, carbon reduction, and QCC, to continuously improve supply chain management. It also aimed to help local high-tech industrial process suppliers with strong technical capabilities but weak competitiveness in systems and processes to improve quality control and optimization. Through integration, it aimed to enhance the output and quality of Taiwan's EUV supply chain team, reaching the target of 70% outsourcing, 30% in-house production, and zero defects. It also prioritized resources for R&D and trial production of advanced processes to maximize integration benefits and achieve a win-win-win situation for customers, Gudeng, and supply chain partners.

Documentary on the achievements of how Gudeng leading supply chains in reducing carbon emissions by 1,160 tons in 2023.

Supplier Management Strategy

As a leader in advanced process photomasks and wafer carriers, Gudeng Precision is committed to promoting sustainable development in the supply chain. Suppliers are required to comply with conflict minerals regulations, green product procurement standards, and ethical business practices to ensure safe working conditions, dignified labor relations, and compliance with ethical standards in their operations, as well as a commitment to environmental protection. Before cooperating with any new supplier, Gudeng Precision requires them to sign a "Supplier Commitment Letter", ensuring that the supply chain complies with the latest global social responsibility standards issued by governments. The commitment covers labor, health and safety, environmental protection, business ethics, and management systems. It aims to fulfill social responsibility, promote a balance between economy, society, and environmental ecology for sustainable development, and continuously conduct sustainable risk assessments.

1.Responsibility Standards

Gudeng Precision requires all suppliers to sign "Ethical Code of Conduct Compliance Statements", "Conflict Minerals Non-Use Declaration", and "Protection of Company Intellectual Property and Customer Privacy" contracts to prevent any unfair, unjust, or discriminatory behavior in procurement activities.

2.New Supplier Evaluation Policy

In addition to assessing technical and quality requirements, all new suppliers (excluding fee-type suppliers) must commit to complying with local laws, ethics, environmental regulations, and not using conflict minerals according to the RBA Responsible Business Alliance Code of Conduct. They must complete the "Supplier Commitment Letter" before receiving orders. If the new supplier belongs to a high environmental impact category (e.g., plating, painting, anodizing), they must provide pollution prevention plans, reports, or approval documents from government agencies to pass the new supplier evaluation. They will also be subject to periodic audits.

Supplier Social Responsibility Requirements

| Item | 2020 | 2021 | 2022 | 2023 |

|---|---|---|---|---|

| Number of new suppliers | 87 | 151 | 149 | 91 |

| Percentage of signed social responsibility commitment letters | 89% | 100% | 100% | 100% |

3.Risk Identification

Gudeng Precision conducts regular risk assessments on its major direct raw material, outsourced processing, and critical material suppliers each year to confirm the risk level of cooperation with these suppliers. In addition to evaluating aspects such as quality, service, delivery, and price, critical suppliers are also required to complete a self-assessment form for environmental health and safety management.

In 2023, 34 suppliers were audited, and the assessment results were as follows: A grade for 28 suppliers, B grade for 6 suppliers, and no C or D grade high-risk suppliers. Suppliers rated as CD grade in the risk assessment are classified as "high-risk projects", and they will be notified to improve within a specified period. The company will continuously support and guide the suppliers in implementing the RBA (Responsible Business Alliance) guidelines based on the audit results. The suppliers will be informed to provide improvement plans for abnormal assessment items within one month, and the Quality Control Unit will confirm the progress of improvements. If no improvement is made, the "Supplier Assistance Program" will be initiated, prioritizing assistance for all non-compliant audit items.

- Due to the shortage of international raw materials caused by the pandemic in 2021, Gudeng Precision managed to meet the expectations of semiconductor customers in critical plastic materials, thanks to the support of A-grade suppliers, ensuring the production capacity as scheduled.

4.Conflict Minerals

Gudeng Precision is committed to conducting detailed investigations into gold (Au), tantalum (Ta), tungsten (W), cobalt (Co), tin (Sn), and other minerals used in its products and production processes. These minerals must not be sourced from conflict regions in the Democratic Republic of the Congo or obtained through illegal smuggling routes.

With business growth in 2023 and an increase in procurement quantities compared to 2021, Gudeng Precision improved its conflict minerals management system. The company rechecked the supply chain raw materials, identified the applicable classification of conflict minerals in its products, and screened suppliers that require further investigation on conflict minerals. Standard investigation tools defined by the Responsible Minerals Initiative (RMI) were used, and all suppliers who passed the conflict minerals investigation were required to provide Conflict Minerals Reporting Template (CMRT) reports. A total of 27 critical suppliers were audited for RMI conflict minerals compliance, ensuring that Gudeng's supply chain does not use conflict minerals in its raw materials.

- In 2023, all products supplied by Gudeng Precision were confirmed to be free of conflict minerals.

5.Restricted Substances

While some of Gudeng Precision's raw materials may contain restricted substances due to product characteristics to meet customer demands, the company actively develops and researches raw materials without using restricted substances to provide to its customers. Packaging materials provided by suppliers comply with RoHS and Halogen-Free specifications.

6.Intermittent Meetings with Critical Suppliers

Gudeng Precision does not demand a bidding process from its EUV (Extreme Ultraviolet) critical supply chain partners. Instead, each supplier is offered a unified and excessive profit based on the proportion of orders determined by quality and delivery. This approach allows suppliers to focus on quality issues, as stable quality leads to stable orders without the need for price competition. Regular meetings are held with EUV critical suppliers to communicate quality deployment and review anomalies to achieve two-way communication and stable quality objectives.

7.Supplier Conference

Every year, Gudeng Precision invites suppliers from around the world to participate in the conference. The conference is opened by the Chairman of Gudeng, encouraging suppliers and Gudeng Precision to jointly commit to the "Net Zero Carbon Emissions" strategy and further understand the Responsible Business Alliance Code of Conduct. The conference advocates supply chain compliance with the highest social, environmental, and ethical standards to ensure that employees and partners are treated well and maintain integrity in operations. The conference covers supply chain goals, quality, and procurement policy advocacy, aiming to achieve direct communication with suppliers and foster a close, trust-based cooperation to continuously improve quality, delivery, cost, and environmental safety, while enhancing supply chain management through technical guidance and face-to-face communication.

To achieve a high local procurement ratio, Gudeng Precision promotes supplier quality improvement policies by implementing statistical process control (SPC), managing hazardous substances such as RoHS, tracking supplier material quality, analyzing quality characteristics, and discussing optimization strategies with suppliers. Regular assessments and evaluations are carried out to achieve the goal of 100% yield. In 2023, 107 exempt materials were identified, significantly reducing inspection work.

Gudeng Precision, with 25 years of experience, has been deeply committed to technology and quality, adhering to semiconductor supply guidelines, and has successfully broken into the market to create Asia's only and the world's second Extreme Ultraviolet Photomask Pod (EUV-Pod).

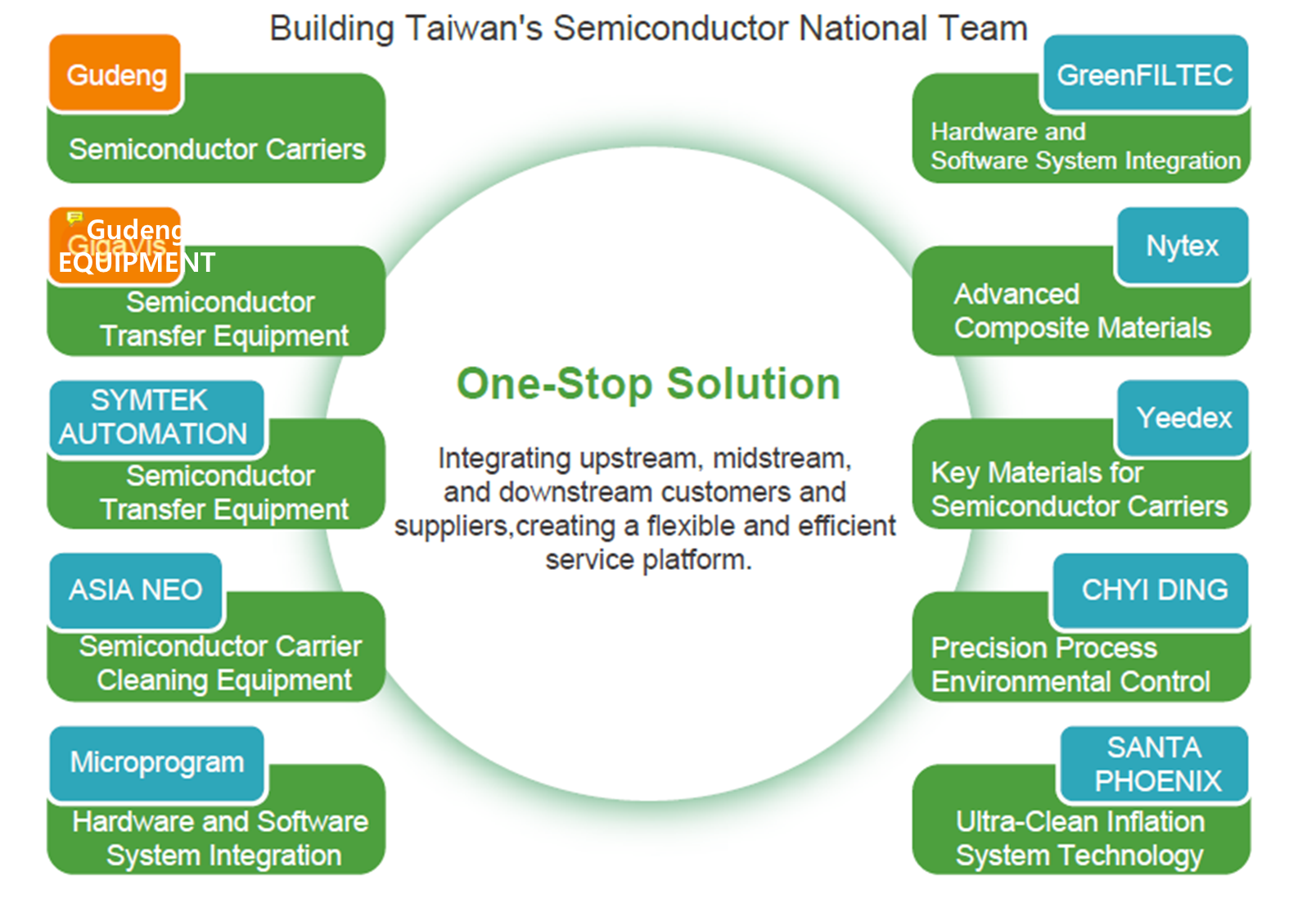

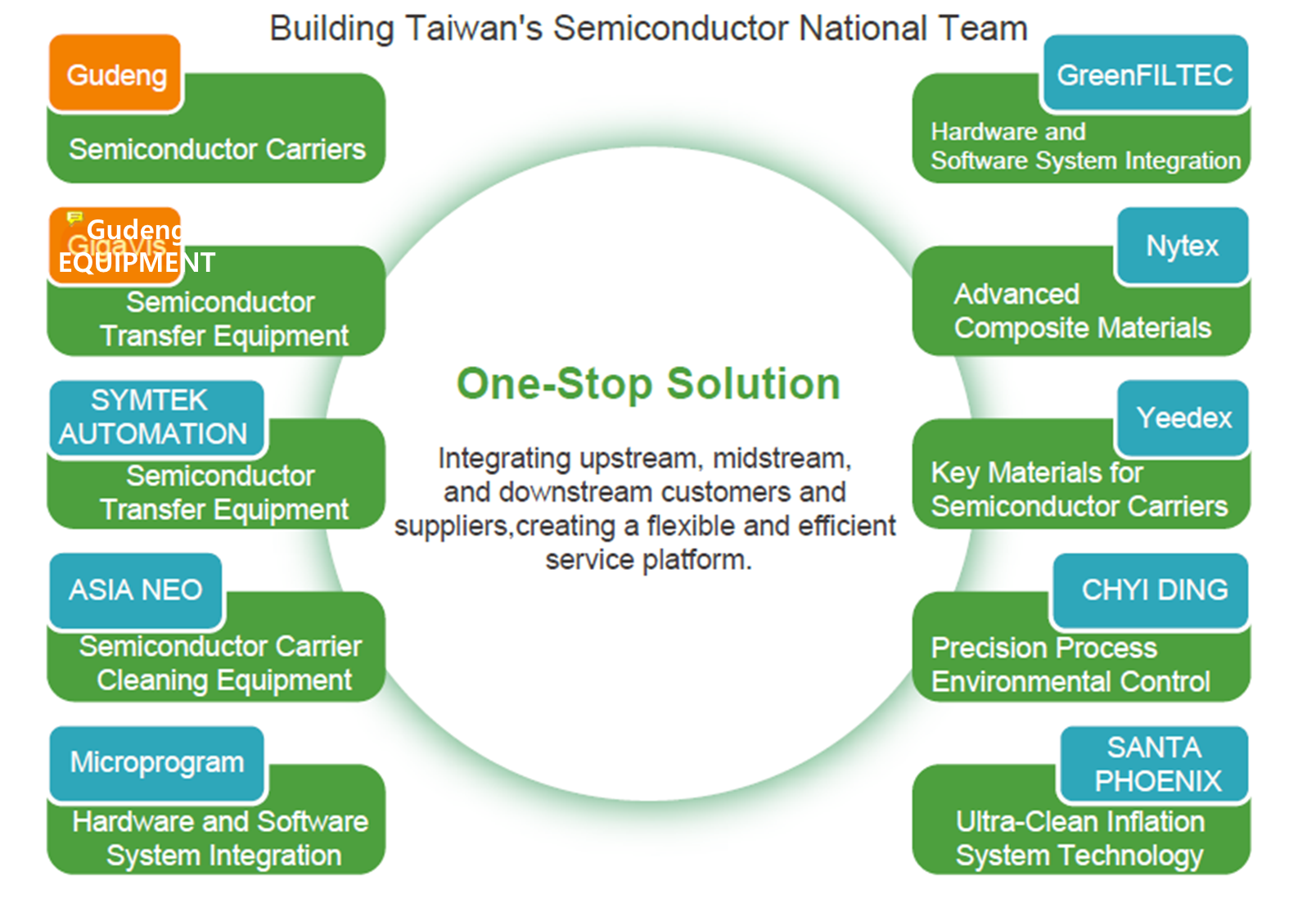

In 2023, Gudeng aimed to share its experience and cooperate with multiple semiconductor upstream, midstream, and downstream suppliers to build Taiwan's national semiconductor team and strengthen the semiconductor supply chain's resilience.

Through the integration of critical global materials and innovative technologies, Gudeng successfully overcame uncertainties caused by industry cycles, economic development, and geopolitical factors during the past year. The company developed next-generation carrier solutions and transportation equipment for customers, successfully integrating four alliance members to establish an all-in-one service for automatic transmission and cleaning of wafer and photomask pods, as well as micro-contamination control of wafer box housings inside semiconductor fabs during the pandemic, driving high operational growth and marking a new milestone for the semiconductor industry.

Chairman of Gudeng (in the middle) leading four alliance members to establish an all-in-one service which marking a new milestone for the semiconductor industry.

Gudeng Precision also leverages the "Gudeng Precision Co-Creation Innovation Service Platform" to collaborate with external supply chain integration of information systems, technical guidance, labor support, and funding to assist several local enterprises in enhancing their technical capabilities through technical integration. By gathering internal R&D, business, and supply chain units, Gudeng establishes an SQM supply commodity quality system with a complete and effective supplier management method and operating model, integrating resources, technical requirements, labor support, and funding to build a solid and complete local supply chain. This helps related equipment manufacturers transform from relying solely on imports to locally producing semiconductor equipment and jointly serving world-class semiconductor customers, providing local suppliers with the opportunity to enter the global semiconductor supply chain and strengthening the leadership position of the semiconductor national team, which is the group's vision.

2023 Proportion of local procurement: 79%

Procurement Amount Ratio

| Item | 2020 | 2021 | 2022 | 2023 |

|---|---|---|---|---|

| Domestic | 563,906,550 | 913,304,309 | 1,864,805,325 | 1,553,193,900 |

| International | 216,443,495 | 261,424,600 | 496,022,135 | 425,040,150 |

| Total Amount | 780,350,045 | 1,174,728,909 | 2,360,827,460 | 1,978,234,050 |

| Localization Proportion | 72% | 78% | 79% | 79% |

Number of manufacturers

| Item | 2020 | 2021 | 2022 | 2023 |

|---|---|---|---|---|

| Number of Domestic manufacturers | 380 | 476 | 536 | 622 |

| Number of International manufacturers | 16 | 20 | 21 | 26 |

| Total | 396 | 496 | 557 | 648 |

| Localization Proportion | 96% | 96% | 96% | 96% |

Creating the Semiconductor Onshore Supply Chain Alliance

Over the past years, globalization has established a comprehensive semiconductor division of labor worldwide, leading to key equipment and materials being controlled by only a few major manufacturers. Without a track record of serving any wafer fab, it is challenging to become a key supply chain member for semiconductor fabs.

Gudeng Precision, with 25 years of experience, has been deeply committed to technology and quality, adhering to semiconductor supply guidelines, and has successfully broken into the market to create Asia's only and the world's second Extreme Ultraviolet Photomask Pod (EUV-Pod).

In 2023, Gudeng aimed to share its experience and cooperate with multiple semiconductor upstream, midstream, and downstream suppliers to build Taiwan's national semiconductor team and strengthen the semiconductor supply chain's resilience.

Through the integration of critical global materials and innovative technologies, Gudeng successfully overcame uncertainties caused by industry cycles, economic development, and geopolitical factors during the past year. The company developed next-generation carrier solutions and transportation equipment for customers, successfully integrating four alliance members to establish an all-in-one service for automatic transmission and cleaning of wafer and photomask pods, as well as micro-contamination control of wafer box housings inside semiconductor fabs during the pandemic, driving high operational growth and marking a new milestone for the semiconductor industry.

"Global Integrated Service Provider for Critical Materials and Innovative Technologies"

Building Taiwan's Semiconductor National Team

Building Taiwan's Semiconductor National Team

Chairman of Gudeng (in the middle) leading four alliance members to establish an all-in-one service which marking a new milestone for the semiconductor industry.

In terms of semiconductor materials,

Gudeng collaborates with material suppliers on advanced composite materials to continuously research and develop materials solutions that offer long-term stability and optimal cleanliness for customers, while enhancing AMC micro-contamination control according to customer specifications.

In the semiconductor equipment segment,

Gudeng and its partner manufacturers work closely together to provide comprehensive semiconductor equipment, including cleaning machines and storage cabinets. Additionally, with long-term cooperation with multiple foundry manufacturers, Gudeng gradually established a complete off-site backup mechanism to provide supply assurance to global customers, allowing Taiwan to overcome regional influences and robustly face any potential market risks Gudeng Precision also leverages the "Gudeng Precision Co-Creation Innovation Service Platform" to collaborate with external supply chain integration of information systems, technical guidance, labor support, and funding to assist several local enterprises in enhancing their technical capabilities through technical integration. By gathering internal R&D, business, and supply chain units, Gudeng establishes an SQM supply commodity quality system with a complete and effective supplier management method and operating model, integrating resources, technical requirements, labor support, and funding to build a solid and complete local supply chain. This helps related equipment manufacturers transform from relying solely on imports to locally producing semiconductor equipment and jointly serving world-class semiconductor customers, providing local suppliers with the opportunity to enter the global semiconductor supply chain and strengthening the leadership position of the semiconductor national team, which is the group's vision.

- Within 2 years, combine with 10 supply chain companies so that the whole carbon reduction plan can achieve a reduction of 2,846 metric tons of CO2 .

- In 2023,with the guidance of of 30 supply chain companies, It is expected that within two years, the carbon reduction performance will jointly achieve 10,000 tons of CO2e.

Supply Chain Carbon Reduction Coaching Program

In response to the international trend of net-zero carbon emissions and the semiconductor customers' demand for sustainability and environmental protection, Gudeng Precision collaborates with the Industrial Development Bureau to carry out vertical cooperative carbon reduction guidance with 10 supply chain companies. The program involves on-site visits to promote energy-saving and carbon reduction projects and aims to improve the overall carbon reduction effect through systematic operation and guidance.

The implementation of the program targets Gudeng Precision and its supply chain companies, forming a system promotion organization. The Industrial Development Bureau guides Gudeng Precision's promotion organization to conduct greenhouse gas inventory checks and key product carbon footprints, combining sustainable and lean management methods. They also assist Gudeng Precision and its supply chain companies in carbon reduction coaching, setting carbon reduction targets, planning carbon reduction paths, and utilizing optimization and feasible carbon reduction technologies to achieve system-wide carbon reduction results.

In 2023, the focus was on six major work items:

System Carbon Reduction Coaching, Lean Management Coaching, Product Carbon Footprint Inventory, Organizational Greenhouse Gas Check, Certification, Smart Energy Management System Implementation, Education and Training, and System Communication Activities.

Project Highlights:

Carbon reduced achievement

- Starting in mid-2022, regular meetings were held with the 10 supply chain companies, and on-site inspections were conducted to assess energy usage and equipment conditions and explore energy-saving potentials.

- The carbon reduction achieved in 2022 was 1,160 metric tons of CO2e per year, accounting for 41% of the total carbon reduction.

- The projected carbon reduction for the executed program in 2023 is 588 metric tons of CO2e per year, accounting for 21% of the total carbon reduction.

- The projected carbon reduction for the executed program in 2024 is 1,098 metric tons of CO2e per year, accounting for 38% of the total carbon reduction.

Energy-saving Benefit

- The planned energy-saving benefit is 5.6 million kWh per year (the total pre-coaching electricity consumption of the system members in 2021 was approximately 37.04 million kWh per year).

Sustainable Lean Improvement Benefit

- The system's energy-saving cost is estimated to save approximately NT$17.99 million per year.

In October 2023, an educational training workshop on carbon reduction blueprints was held.

Professional coaching consultants were commissioned to explain global climate change issues, RE100, and net-zero carbon emission trends to participating companies. They shared global benchmark examples of energy-saving and carbon reduction, and conducted open Q&A sessions to encourage diverse feedback.

End-of-2023 Carbon Reduction Achievement Presentation Event

For the 1-year first-stage coaching plan with the 10 supply chain companies, 44 energy-saving improvement plans were launched in 6 categories. Additionally, the installation of sensors on the overhead lights of processing machines in each plant was promoted to reduce unnecessary energy consumption. Planned production suspension schedules were implemented, and unnecessary compressed air pipelines and fittings were removed to reduce air leakage and electricity wastage, integrating energy-saving and carbon reduction awareness into daily operations.

For 2023, priority assistance will be given to 2 supply chain companies to continuously install solar photovoltaic systems on idle roofs, gradually increasing the proportion of renewable energy use. It is expected to achieve a greenhouse gas reduction of 370 metric tons and an energy-saving of 727,120 kWh by 2024, saving NT$2.93 million in electricity costs.

| Category | Number of Improvement Proposals | Energy-saving Benefits (kWh/year) |

Energy-saving Costs (NT$10,000/year) |

Greenhouse Gas Reduction (ton-CO2e/year) |

|---|---|---|---|---|

| Manufacturing Processes | 6 | 1,044,496 | 298 | 532 |

| Compressed Air | 21 | 566,976 | 187 | 288 |

| Lighting | 6 | 469,650 | 124 | 239 |

| Air Conditioning | 7 | 191,236 | 52 | 97 |

| Common Areas | 1 | 7,833 | 2 | 4 |

| Electricity | 3 | 0 | 114 | 0 |

| Total | 44 | 2,280,191 | 777 | 1,160 |

Supply Chain Low Carbon Transformation long-term Project

To accelerate low-carbon transformation, Gudeng Precision plans to introduce a digital carbon management platform, encompassing organizational greenhouse gas management modules, sustainable supply chain management modules, and product carbon footprint management modules, involving the coaching of 30 supply chain companies to comply with ISO 14064-1 and ISO 14067 standards. This will be achieved through data integration, collection, calculation, and quantification methodologies provided by consulting professionals to maintain systematic logic, providing management with directions for carbon reduction and setting supply chain carbon reduction goals.

By the end of 2023, Gudeng will continue to contact the supply chain system, planning to launch the project in 2023. The company will also adopt ISO 20400 sustainable procurement to provide a systematic and more efficient procurement operation while encouraging suppliers to join the sustainable development ranks. It is expected that within two years, the carbon reduction performance will jointly achieve 10,000 tons of CO2e.

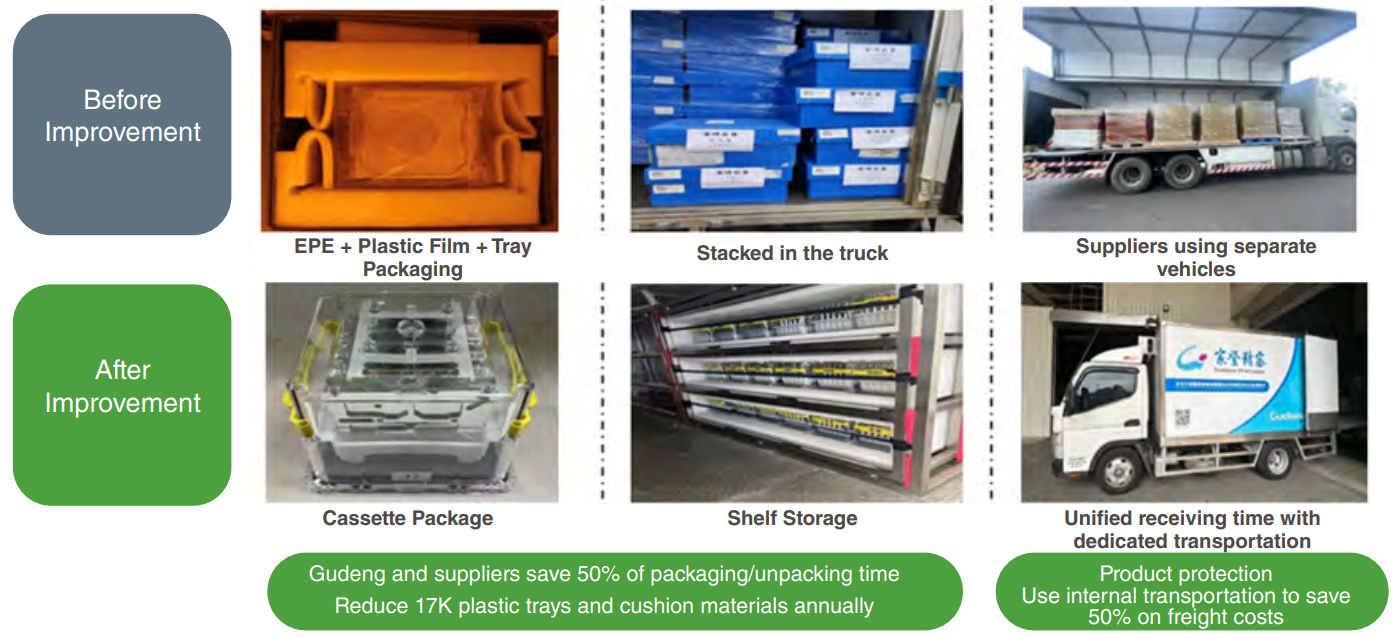

Product Packaging Plastic-Free

In response to climate change measures between clients, Gudeng Precision will focus on key product packaging designs using reusable materials for shipping and recycling materials for shipments to customers, promoting the concept of environmental protection and conservation. This concept will also be promoted jointly with suppliers, with the plan to extend it to other product applications continuously.

Case Study: Improving EIP's Packaging and Stacking Methods to Achieve "Plastic-Free Three Savings", Space-saving, Time-saving, Labor-saving, and Eliminating Single-use Plastics.