Sustainable Environment

In 2023, we made commitments to key customers concerned about

climate change and

declared environmental sustainability goals:

2030

Use 60% renewable energy

2035

Use 90% renewable energy

2040

Use 90% renewable energy

Achieve in 2040 :

EV100

RE100

EP100

| TCFD Climate Risk Disclosure Framework | |

|---|---|

| Governance | Disclose the Board of Directors' and sustainability committee's tracking and management progress on climate-related risks and opportunities. |

| Strategy | Identify short-term, medium-term, and long-term climate risks and opportunities for operations and finances and develop corresponding response strategies. |

| Risk management | Identify climate risks, assess and establish risk management systems. |

| Index and Goals | Disclose plans for addressing climate change risks. |

Climate Change Governance and Targets

Climate change is a matter of great concern for stakeholders of Gudeng Precision, and the

company actively tracks global policy trends. It has developed a climate change management

plan concerning greenhouse gas emissions, energy management, water resources, waste, and

renewable energy.

| Policy and Commitment | Energy management Carbon reduction for all employees | ||||

|---|---|---|---|---|---|

| Policy | 2023 Goal | 2023 Achievements | 2024 Goal | Long-term Goals | |

| Energy management | Improve energy efficiency and effectively utilize energy resources. |

|

|

|

Improve energy efficiency and effectively utilize energy resources. |

| Greenhouse Gas Management | - Promote greenhouse gas inventory, disclosure, and reduction to achieve net-zero emissions. |

|

|

|

Promote greenhouse gas inventory, disclosure, and reduction to achieve net-zero emissions. |

| Water Resource Management | Improve water use efficiency, promote water recycling, and reduce discharge. | Install recycled water systems to enhance water resource efficiency. | Install recycled water systems to enhance water resource efficiency. |

|

Improve water use efficiency, promote water recycling, and reduce discharge. |

| Waste Management | Waste Reduction and Recycling, Promoting Circular Economy. | Plastic recycling and reuse. |

|

|

Waste Reduction and Recycling, Promoting Circular Economy. |

To achieve these goals and mitigate the impacts of climate risk, the factory has implemented ISO 14064-1 and ISO 50001 management systems. It conducts data inventory and evaluation and tracks improvement progress through the Operations Continuity and Risk Management Team. The team reports to the Sustainability Committee and the Board of Directors every quarter to discuss response strategies.

Currently, our mission is low-carbon transformation and smart manufacturing. Considering short, medium, and long-term market changes, the Board of Directors approved a 50 MW solar power plant investment project in 2023 and prioritized the development of fish-power symbiosis, direct power supply, and aimed to achieve RE100 before 2030.

Climate Change Risk Management and Response Strategies

| Main Climate Change Risks | Potential operational and financial impacts | Response Strategies | |

|---|---|---|---|

| Market Change Risks |

|

|

|

| Policy and Legal Risks |

|

|

|

| Acute Extreme Weather Risks |

|

|

|

| Chronic Progressive Climate Risks |

|

||

Climate Change Opportunities and Response Strategies

| Main Climate Change Opportunities | Potential operational and financial impacts | Response Strategies | |

|---|---|---|---|

| Market Change Opportunities |

|

|

|

| Brand Reputation Opportunities |

|

|

|

Gudeng Precision supports climate change publicity program

In 2023, a total of 12 energy-saving action plans were promoted which made energy-saving amount reached 1.95 million kWh with energy-saving rate 5.32% and further reduce carbon 389 tons of CO2 equivalent.

| Policy and Commitment | Energy management Carbon reduction for all employees | ||||

|---|---|---|---|---|---|

| Policy | 2023 Goal | 2023 Achievements | 2024 Goal | Long-term Goals | |

| Energy management | Improve energy efficiency and effectively utilize energy resources. |

|

|

|

Improve energy efficiency and effectively utilize energy resources. |

Energy Management Policy.

1.Improving energy efficiency and reducing energy usage costs.

2.Implementing energy-efficient and eco-friendly designs, prioritizing the procurement of energy-saving equipment.

3.Implementing energy management systems to continuously improve energy performance.

4.Complying with energy-related regulations and establishing a sustainable green operation.

5.Encouraging all employees to participate in communication and coordination to achieve energy-saving and carbon-reduction goals.

Energy Management Implementation Results

- Implemented ISO 50001 Energy Management System guidance and third-party verification: Selected by the Ministry of Economic Affairs Industrial Bureau for "Manufacturing Industry Energy Management Demonstration Project", introduced demonstration team guidance, established an energy management team in May 2023, conducted energy audits and energy regulation identification, promoted action plans and implemented energy-saving diagnosis, established baselines and benchmarks, and monitoring methods, completed internal audits and management reviews, and obtained third-party verification in November 2022. Through the operation of the energy management system, it has achieved substantial benefits in improving energy efficiency, reducing energy costs, and decreasing greenhouse gas emissions.

- Installation of Smart Electricity Meters and Monitoring Systems : Due to the increase in factory production capacity in 2023, electricity consumption has continued to grow. A smart energy management system was introduced to integrate existing digital electricity meters and there is a plan to install an additional 230 digital electricity meters to monitor major energy-consuming equipment. The overall construction project is expected to be completed in the second quarter of 2023. The establishment of a comprehensive power information system will provide decision-making references for power-saving and improvement performance management policies and provide alerts for abnormal power usage to facilitate energy-saving countermeasures. Additionally, plans are underway to increase carbon emission analysis charts and advanced data displays to facilitate comparisons of carbon emissions during different periods and for various sub-items.

- We will continue to optimize our energy management strategy :

Note: Energy Saving Amount for the Scheme: The energy-saving amount achievable in one year through this scheme.

NO Action Plan Name Description of Measures Annual Energy Saving Amount (kWh) Completion Date 2023 Energy Saving Amount (kWh) 1 Replacement of Energy-saving Lamps in the Office Area. Replace the remaining T5-28W lamps in the office area with LED lamps (quantity: 100). 10,800 2023/11/30 900 2 Energy-saving Improvement of Cleanroom Lighting Fixtures Adjust the lighting fixtures in the storage area of the cleanroom. Reduce the number of lighting fixtures in the storage area (from 1,805 units to 1,516 units) without affecting the lighting standards required by regulations and the use by personnel. 41,616 2023/6/30 20,808 3 Reduction of Cleanroom FFUs Reduce the operation of FFUs in the cleanroom to lower air conditioning electricity consumption. Reduce 30% (502 units) of the total FFU operating quantity in areas B, C, E, F, and J of the cleanroom, without affecting the cleanroom's design level. 526,257 2023/7/31 219,274 4 Improvement of Condenser Temperature to Reduce Chiller Power Consumption Clean the condenser and improve the condenser's approach temperature to reduce chiller power consumption. 56,448 2023/6/30 28,224 5 Reduced Mixing Water to Increase the Chilled Water Supply Temperature for Air Conditioning Electricity Savings. Gradually reduce the frequency of the main chilled water pump's pressure control to reduce the mixing of return water. 77,433 2023/6/30 38,717 6 Adjustment of the Compressed Air Machine Pressure Setting to Reduce Compressed Air System Electricity Consumption. Adjust the compressed air machine's pressure setting to reduce pressure drops and decrease compressed air machine power consumption. 120,852 2023/6/30 60,426 7 Air Conditioning Chiller Energy-saving Control. The start-up number of air conditioning chillers is traditionally based on past experience, switching the number of chillers based on the air conditioning load. Now, it has been changed to select the appropriate start-up sequence and number of chillers based on the air conditioning load to reduce air conditioning power consumption. 42,000 2022/9/30 10,500 8 Energy-saving Improvement of Injection Molding Machine Raw Material Dryers. Improve the raw material dryers above 24 injection molding machines by adding insulation to the raw material barrels while introducing waste heat from the lower heating barrels and eliminating electric heating, reducing the electricity consumption of the upper raw material dryers. 225,000 2023/11/30 18,750 9 CNC Air Conditioning Change to Central Air Conditioning Supply for 3F. Adjust the air conditioning supply unit for the 1F CNC production area, update the air conditioning pipeline, and supply it from the 3F production area to improve the efficiency of 3F air conditioning units and reduce the overall number of air conditioning units, achieving energy-saving effects. 294,074 2023/3/31 220.556 10 Lower Pressure for Pure Water Supply to Optimize Electricity Consumption. Adjust the pure water supply pressure from 4.5 kg (motor frequency of 54 Hz) to 3.0 kg (motor frequency of 36 Hz) in the latter stage. This will reduce the operating frequency of the water supply motor (the water supply pump motor is 11 kW, and the booster pump motor is 15 kW), thus reducing energy consumption. 116.521 2023/6/30 58,261 11 Optimization of Chiller Water Pump Motor Frequency Control for the 3F Air Conditioning System The original setting for the cooling water motor in the 3F air conditioning system was fixed-frequency operation. After discussions with the original manufacturer, it was revised to variable frequency control (cooling water pump motor operating frequency reduced from 60Hz to 45Hz). This adjustment can reduce the operating frequency of the water supply motor and lower energy consumption. 301,414 2023/9/30 75,354 12 Optimization of Chiller Water Pump Motor Frequency Control for the 3F Air Conditioning System The original setting for the cooling water motor in the 3F air conditioning system was fixed-frequency operation. After discussions with the original manufacturer, it was revised to variable frequency control (cooling water pump motor operating frequency reduced from 52Hz to 40Hz). This adjustment can reduce the operating frequency of the water supply motor and lower energy consumption. 138,683 2023/9/30 34,671 Total 1,951,098 786,441

Note: 2023 Energy Saving Amount: The actual energy-saving achieved from the completion date of the scheme until December 31, 2023 (calculated according to energy audit reporting rules).

| Policy and Commitment | Energy management Carbon reduction for all employees | ||||

|---|---|---|---|---|---|

| Policy | 2023 Goal | 2023 Achievements | 2024 Goal | Long-term Goals | |

| Greenhouse Gas Management | Promote greenhouse gas inventory, disclosure, and reduction to achieve net-zero emissions. |

|

|

|

Promote greenhouse gas inventory, disclosure, and reduction to achieve net-zero emissions. |

| Category | Category Description | 2022 | 2023 |

|---|---|---|---|

| Category 1 | Direct greenhouse gas emissions and removal. | 535.75 | 584.70 |

| Category 2 | Indirect greenhouse gas emissions from purchased energy. | 6,873.31 | 6,561.37 |

| Category 3 | Indirect greenhouse gas emissions from transportation. | 4.47 | 11.63 |

| Category 4 | Indirect Greenhouse Gas Emissions from Products Used by the Organization. | 1,349.81 | 1,529.28 |

| Category 5 | Indirect Greenhouse Gas Emissions Associated with the Use of the Organization's Products. | - | - |

| Category 6 | Indirect Greenhouse Gas Emissions Generated from Other Sources. | - | - |

| Total | 8,763.34 | 9,686.98 | |

| Greenhouse gas emission intensity (metric tons of CO2 equivalent/million revenue) | 3.71 | 2.58 | |

Unit: metric tons of CO2 equivalent

Note:

- Operating control approach is used.

- Category 3 inventory scope includes emissions from air travel and high-speed rail travel. Category 4 includes emissions from purchased electricity, tap water, and diesel fuel, as well as solid and liquid waste treatment. Categories 5-6 are not included in the inventory scope and are marked with "-".

- The electricity emission factor in Category 2 is based on the 2021 electricity emission factor published by the Energy Bureau, Ministry of Economic Affairs: 0.509 kg CO2e/kWh.

- Global warming potential (GWP) values are referenced from the IPCC 2021 Sixth Assessment Report.

- Greenhouse gas emission factors: Environmental Protection Administration, Executive Yuan EPA Greenhouse Gas Emission Factor Management Table 6.0.4.

- Inventory scope for 2021: October 2022, Tucheng Headquarters, Tree Valley Factory, Tainan Science Factory.

- Inventory scope for 2022: June 2023, Tucheng Headquarters, Tree Valley Factory, Tainan Science, Fuxing Factory.

- Greenhouse gas emission intensity = (Category 1 + Category 2)/million in revenue.

| Policy and Commitment | Energy management Carbon reduction for all employees | ||||

|---|---|---|---|---|---|

| Policy | 2023 Goal | 2023 Achievements | 2024 Goal | Long-term Goals | |

| Water Resource Management | Improve water use efficiency, promote water recycling, and reduce discharge. | Install recycled water systems to enhance water resource efficiency. | Install recycled water systems to enhance water resource efficiency. |

|

Improve water use efficiency, promote water recycling, and reduce discharge. |

Gudeng Precision mainly uses water for production processes and daily employee use, and the factory's water source is entirely obtained from third-party sources (Taiwan Water Corporation). No surface fresh water, seawater, or well water is used. Wastewater treatment is carried out in accordance with government regulations and follows the guidelines of various industrial parks. The treated wastewater is discharged into the wastewater treatment plants in the respective industrial parks, meeting the discharge standards set by each industrial park. The domestic wastewater from the headquarters is also discharged into the sewage system according to regulations, including third-party endpoints and seawater.

| Items | 2022 | 2023 |

|---|---|---|

| Water Intake | 74.78 | 89.17 |

| Water Discharge | 24.47 | 33.20 |

| Water Consumption | 50.31 | 55.97 |

| Unit Water Intake per Million in Revenue (million cubic meters per million in revenue) |

0.037 | 0.028 |

Note:

- Water intake, wastewater discharge, and water consumption are measured in million cubic meters.

- The 2021 statistics include the Operations Headquarters, Shugu Plant, and South Science Park Plant. The 2023 statistics include the Operations Headquarters, Tree Valley Plant, Tainan Science Plant, and Fuxing Plant.

- Operations Headquarters, Fuxing Plant, and Tainan Science Plant have no wastewater flow meters installed, wastewater discharge is estimated at 80% of the water intake.

- Water consumption = Water intake – Water Discharge.

Water recycling volume in 2023

✓ The total recycling volume was 52,436m3, and the process water recycling rate was 56.3%.| Program Name | Description of Measures | Water Saving Effect |

|---|---|---|

| Installation of Water Recycling System | The RO system's wastewater is recycled and treated in the water recycling system. The treated water is reused in the industrial process, and the water from the recycling system is used for flushing and cooling towers, increasing the water usage frequency, reducing discharge, and improving water resource utilization. | 9,967 m3/year |

| Policy and Commitment | Energy management Carbon reduction for all employees | ||||

|---|---|---|---|---|---|

| Policy | 2023 Goal | 2023 Achievements | 2024 Goal | Long-term Goals | |

| Waste Management | Waste Reduction and Recycling, Promoting Circular Economy. | Plastic recycling and reuse. |

|

|

Waste Reduction and Recycling, Promoting Circular Economy. |

Gudeng Precision‘s waste mainly includes domestic waste and general business waste and truthfully reports the quantity of waste and entrusts legal vendors for proper handling, ensuring compliance with regulatory reporting procedures during transportation.

Waste Transportation Statistics

| Waste Category | 2022 | 2023 |

|---|---|---|

| Domestic Waste | 35.31 | 49.51 |

| General Business Waste | 188.92 | 309.81 |

| Total | 224.23 | 359.32 |

| Waste Transportation Volume

(tons per million revenue) |

0.112 | 0.114 |

Unit: tons

Waste Classification Statistics

| Waste Type Weight (tons) | Domestic Waste | Waste Plastic | Waste Wood | Waste Paper | Waste Aluminum | Waste Hardware | Total |

|---|---|---|---|---|---|---|---|

| 2021 | 35.31 | 152.80 | 15.98 | 15.75 | 2.68 | 1.71 | 224.23 |

| 2023 | 49.51 | 239.04 | 13.33 | 37.77 | 9.64 | 10.03 | 359.32 |

Unit: tons

Note: 2021 statistics scope: Tree Valley Plant.

Note: 2023 statistics scope: Tree Valley Plant, Fuxing Plant.

Note: 2023 statistics scope: Tree Valley Plant, Fuxing Plant.

In 2023, Gudeng Precision Industrial Co., Ltd., was NOT fined for violating environmental regulations.

Data Source: Transparent Footprint https://thaubing.gcaa.org.tw/

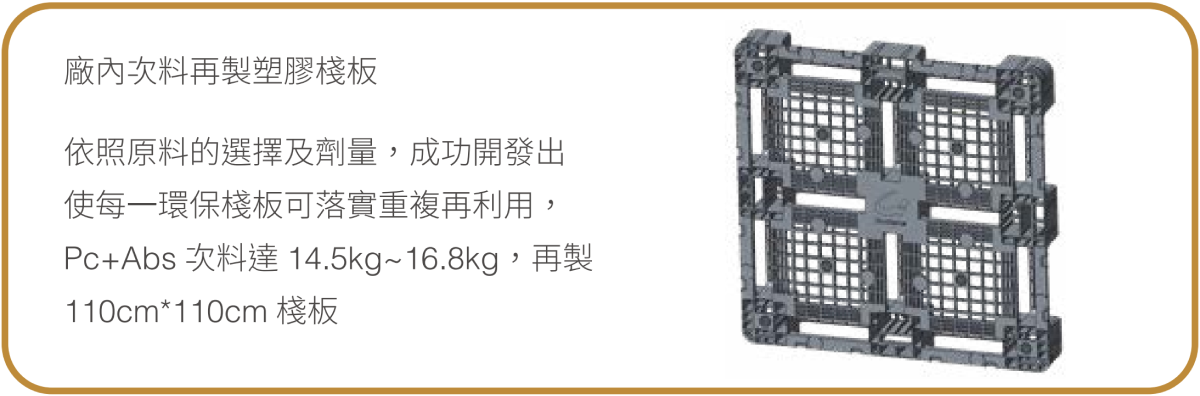

Plastics are the main component of Gudeng Precision's products. The production process often generates supports with injection connections, newly developed NG plastics, and trial-produced plastic waste. Most of these plastics can be recycled and reused. Emphasizing sustainable environmental principles, the company has a full-time material recycling policy.

Gudeng also advocates environmental protection and conservation concepts, such as circular use and recycling.

Since 2018, seven suppliers have responded to the use of plastic pallets made from recycled materials. These pallets are used for back-and-forth transportation, achieving a 100% reuse rate.

Implementation Results:

- The recycling rate of total recycled materials in 2023 reached 100%.

- Recent Purchase of Environmentally-friendly Pallets:

Year 2019 2020 2021 2022 2023 Total Amount 270 460 407 1,901 3,960 6,998 - Three projects to use internal waste to produce recycled plastic pallets :