Sustainable Value

The semiconductor industry is Taiwan's pride, with high barriers

to entry and investment costs. People often ask me what the secret behind Gudeng

Precision's continuous growth year after year since its establishment is. My answer

is simple: "Listen to customers' voices" and "value employee education and

training". By staying close to customers and focusing on talent cultivation

internally, we grow together with our customers as partners. After 25 years of

entrepreneurship, we have broken through barriers repeatedly, with the stock price

surpassing NT$400 and reaching a peak market value. We take responsibility for all

stakeholders.

If the carrier is a "fresh-keeping box", the functionality of our EUV and FOUP products is to prevent impurities, collisions, or scratches on wafers, effectively helping customers improve yield and leading in the mass production of 7nm, 5nm, and 3nm wafers. We have established long-term and professional relationships with key customers.

We invest over NT$100 million annually in research and development to continuously improve our core technology in precision CNC machining. By adopting a focused strategy and targeting key opportunities and products, we have gradually built a unique "Innovative Service Business Model" and realized the innovative value of "Co-Creation". We have integrated an inclusive supply platform for advanced industrial processes. In 2022, we began mass production of our Open Front Opening Unified Pod (FOUP) with a significant increase in demand. Additionally, our aerospace products obtained FAA (Federal Aviation Administration) NADCAP certification in 2023 and passed customer validation.

To meet the demands of future rapid growth, reduce supply chain risks, and mitigate the impact of geopolitical factors, we are constructing factories and offices in Tucheng and Sanxia, creating 1,200 to 1,500 job opportunities. We aim to maximize profits with minimal costs, gather local talents and expertise, and develop a pool of semiconductor professionals in Taiwan.

Economic:

In this year's sustainability report, we highlight product innovation to let all

stakeholders who care about Gudeng's sustainable development know that Gudeng has spent

decades honing its expertise,undergoing numerous transformations to inspire

organizational agility and continuous learning. Our capability to develop Asia's only

world-class technology, EUV Pod, drives the technology toward quality and

intelligence.If the carrier is a "fresh-keeping box", the functionality of our EUV and FOUP products is to prevent impurities, collisions, or scratches on wafers, effectively helping customers improve yield and leading in the mass production of 7nm, 5nm, and 3nm wafers. We have established long-term and professional relationships with key customers.

We invest over NT$100 million annually in research and development to continuously improve our core technology in precision CNC machining. By adopting a focused strategy and targeting key opportunities and products, we have gradually built a unique "Innovative Service Business Model" and realized the innovative value of "Co-Creation". We have integrated an inclusive supply platform for advanced industrial processes. In 2022, we began mass production of our Open Front Opening Unified Pod (FOUP) with a significant increase in demand. Additionally, our aerospace products obtained FAA (Federal Aviation Administration) NADCAP certification in 2023 and passed customer validation.

To meet the demands of future rapid growth, reduce supply chain risks, and mitigate the impact of geopolitical factors, we are constructing factories and offices in Tucheng and Sanxia, creating 1,200 to 1,500 job opportunities. We aim to maximize profits with minimal costs, gather local talents and expertise, and develop a pool of semiconductor professionals in Taiwan.

Environmental:

Our mission is now centered around low-carbon transformation and smart manufacturing.

Externally, we are working with ten supply chain partners to devise 85 energy

improvement plans, successfully reducing carbon emissions by 1,200 tons. In 2023, we

expanded our efforts, guiding 30 supply chain partners in carbon assessment, and setting

a two-year target to reduce carbon emissions by 20,000 tons. Internally, we have

obtained ISO 50001 and 14064 certifications. We formed a power-saving team within the

factory, implementing 12 energy-saving action plans. We made commitments to key clients

concerned about climate change, declaring our intentions to achieve RE100 before 2040

and proactively invest in 50MW solar power plants. We strive to achieve 100% renewable

energy usage by 2030. We continuously review internal processes and conduct assessments

to identify areas where we can further improve and adapt to climate change.

Social:

Employee training and welfare, as well as health and safety, are also significant

concerns for Gudeng Precision. We implement human rights policies, diversity, and gender

equality, which are audited by third-party organizations, earning us a Platinum

certification with a score of 200 from the Responsible Business Alliance (RBA). To

become a world-class organization in cultivating global key material innovation

technology professionals, we have drafted a 10-year talent development plan. We

established the "5531 Talent First" learning behavior guidelines and provided continuous

employee education and training through the "Bill’s Appointment" and "Bill’s Appointment

Training Program". We enable each department to develop its own knowledge management

solutions that address specific needs and situations. We are proud to be the first tech

company in Asia to be ISO 30401 certified for knowledge management and to receive the

highest honor in the field of human resources – the National Talent Development Award.

Giving back to society has always been our founding mission, with a tradition of actively participating in public welfare for decades. We promote sustainable care policies both company-driven and employee-driven, working together to achieve 15 public welfare projects. Our Chairman has initiated fundraising efforts, collaborating with both supply chain and civil organizations to develop a reconstruction plan for schools in Hualien after the earthquake. We continue to invest in five major public welfare projects. In addition, the MA (Management Association) team bravely established a public welfare group, creating the RE+100 Public Welfare Fund and leading two major public welfare activities. We have accumulated 382 participants who actively contribute to public welfare.

However, we recognize that setting up long-term aid plans to care for remote and vulnerable groups' medical quality is a top priority. We envision establishing a public welfare foundation and systematically expanding the scope of public welfare activities, ensuring that the spirit of Gudeng lives on, and continuing our joint efforts.

Looking ahead to the next decade, Gudeng Precision will continue to uphold the highest service quality standards and focus on the growth of three product lines: EUV Mask Carriers, FOUP Wafer Carriers, and aerospace components. Our vision is to "Nurture employees with knowledge, enhance the company through management, impress customers with services, and contribute to society through effectiveness". We aim to be the most reliable partner for leading global semiconductor manufacturers, continuously improving and optimizing ourselves, creating sustainable development, and coexisting and prospering with the land, customers, and employees, walking hand in hand.

𝓦𝓱𝓪𝓽𝓮𝓿𝓮𝓻 𝓽𝓱𝓮 𝓱𝓮𝓪𝓻𝓽 𝓬𝓪𝓷 𝓲𝓶𝓪𝓰𝓲𝓷𝓮,

𝓐𝓷𝓭 𝓫𝓮𝓵𝓲𝓮𝓿𝓮 𝓲𝓷,

𝓦𝓲𝓵𝓵 𝓮𝓿𝓮𝓷𝓽𝓾𝓪𝓵𝓵𝔂 𝓬𝓸𝓶𝓮 𝓽𝓻𝓾𝓮.

𝑮𝒖𝒅𝒆𝒏𝒈 𝑷𝒓𝒆𝒄𝒊𝒔𝒊𝒐𝒏 𝑰𝒏𝒅𝒖𝒔𝒕𝒓𝒊𝒂𝒍 𝑪𝒐., 𝑳𝑻𝑫.

𝑮𝒖𝒅𝒆𝒏𝒈 𝑷𝒓𝒆𝒄𝒊𝒔𝒊𝒐𝒏 𝑰𝒏𝒅𝒖𝒔𝒕𝒓𝒊𝒂𝒍 𝑪𝒐., 𝑳𝑻𝑫.

Ming-Chien Chiu Chairman and Tien-Jui Lin Vice Chairman

About Gudeng Precision

- Establishment Date: March 20, 1998

- Founder:

- Ming-Chien Chiu Chairman and CEO

- Tien-Jui Lin Vice Chirman and General Manager

- Date of Share Capital: NT$942,972,320

- Number of Employees: 640

營運據點

- Headquarters:9th Floor, No. 2, Sec. 4, Zhongyang Rd., Tucheng District, New Taipei City, Taiwan

- Tainan Tree Valley Plant:No. 17-1, Zilian Rd., Xinshi District, Tainan City, Taiwan

- Taipei Fuxing Plant:No. 21, Fuxing St., Tucheng District, New Taipei City, Taiwan

- Tainan Science Branch:2F-1, 2F-2, No. 23, Nanke 3rd Rd., Xinyi District, Tainan City, Taiwan

Mission

Providing global critical materials and innovative technologies

Cultivate

Cultivating global professionals in critical material innovation technology

Vision

The preferred partner for global semiconductor industry leaders in critical material innovation technologies

Business Overview

Gudeng Precision was established in 1998, initially focused on CNC machining of plastic

shell molds. In the second year, we successfully entered the semiconductor front-end

photolithography process equipment and parts field, starting the development of

photolithography process components and forming close partnerships with customers to

provide photomask carrier solution products. To date, Gudeng Precision is the market

leader in high-end photomask carrier solutions.

In 2008, we officially entered the wafer carrier solution market, positioning ourselves as the "Integrated Service Provider of Innovative Technology for Critical Materials Worldwide". We became the first and only Taiwanese company to participate in the international 18-inch semiconductor equipment process development, a critical step for the world's semiconductor process to move towards the next generation – 18 inches (450mm) technology. In 2019, our EUV Pod became the first in Asia and one of only two worldwide to be certified as a critical product by ASML, the world's largest semiconductor equipment manufacturer in the photolithography market. With top CNC technology and precise processing capabilities up to mirror level, it has been applied to product appearance, improving exposure efficiency, reducing rework, and enhancing process yield. It has become a new milestone in the transfer of advanced semiconductor process technology, and a necessary advanced photomask carrier for the mass production of 3-nanometer chips using Extreme Ultraviolet (EUV) lithography by international semiconductor giants, transforming Gudeng Precision from a mold manufacturer in the manufacturing industry to a world-class Taiwanese semiconductor company, creating a unique industry position.

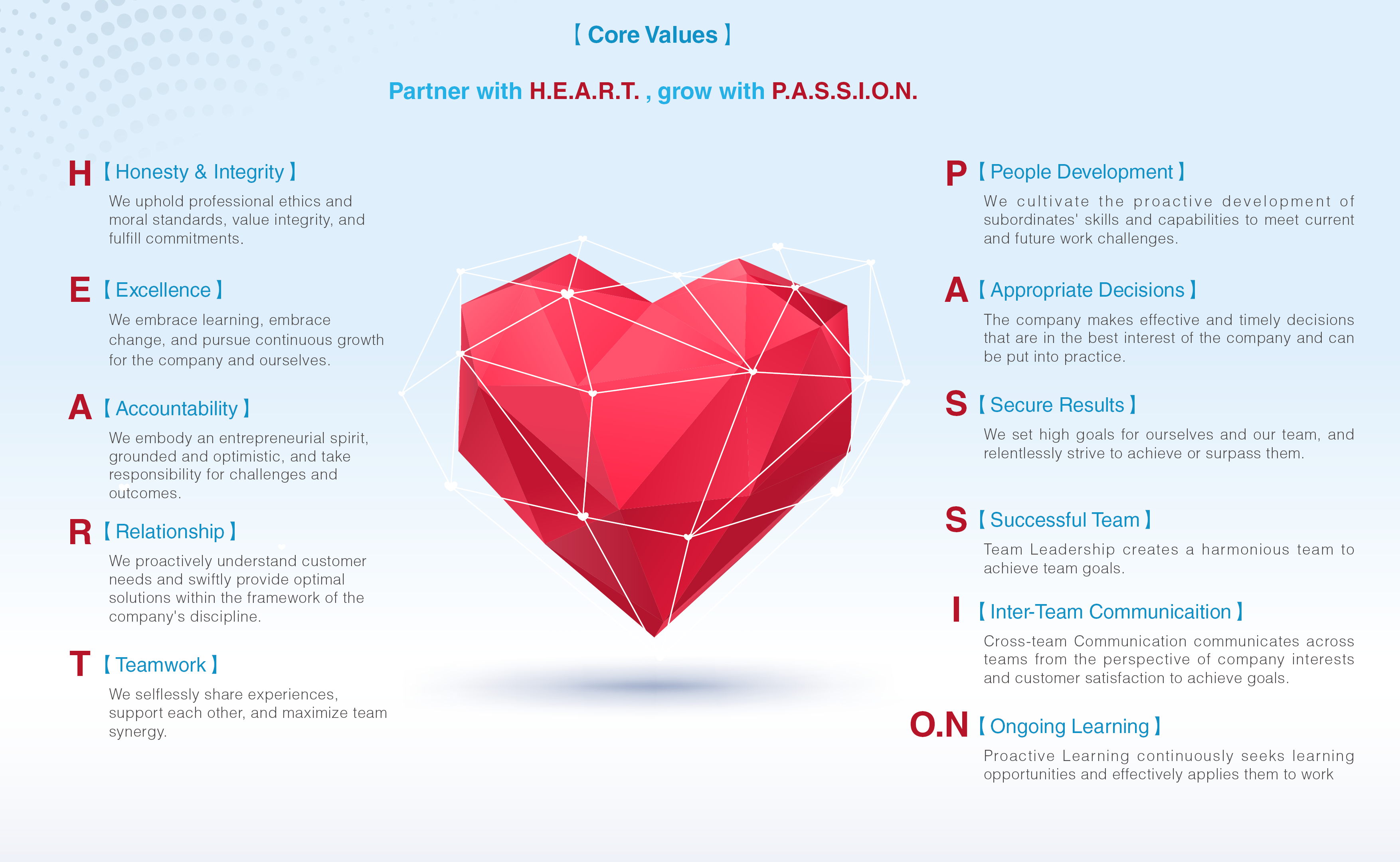

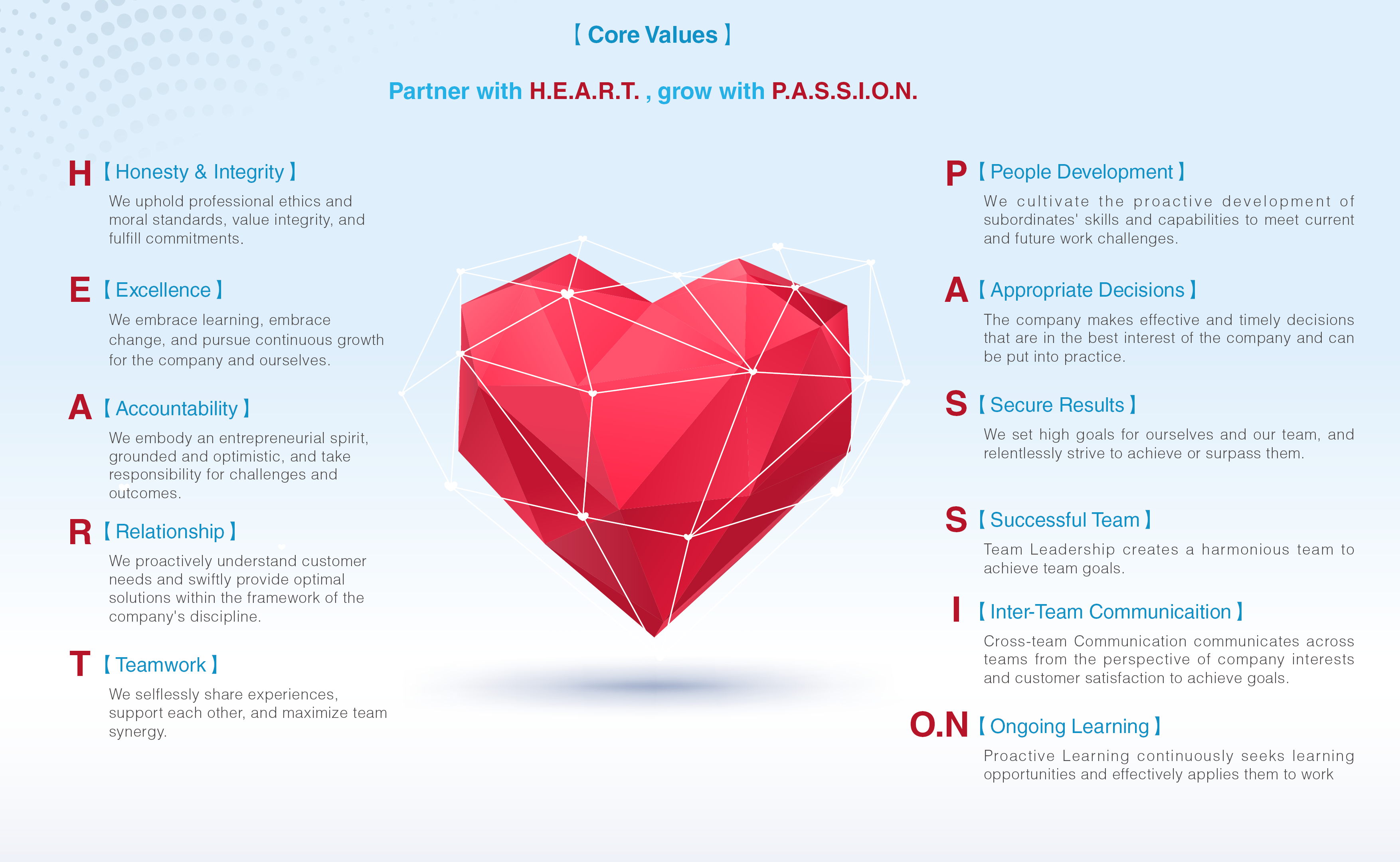

Throughout our journey, we have upheld the principles of technological leadership, product innovation, and long-term trust in our customer partnerships. We are committed to focusing on the semiconductor industry as our core development area, with a comprehensive solution-based approach as our main service strategy. Gradually, we have established a unique "Innovative Service Business Model" based on the core values of "Partner with H.E.A.R.T., Grow with P.A.S.S.I.ON". We emphasize the innovation value of "Co-Creation" and build an integrated supply platform for advanced industry processes.

We firmly believe that "listening sincerely to customer needs and consistently creating value beyond their expectations is the origin of all innovation and the starting point for the sustainable operation of Gudeng Precision".

In 2020, Gudeng Precision officially entered the aerospace field, replicating our successful experiences from the semiconductor industry. We applied our core expertise in precision machining technology to critical aerospace components requiring high-precision processing. Successfully, we impressed customers with quick sample delivery, expanding applications, and a global customer base.

- In 2021, we obtained aerospace AS9100D certification.

- In 2023, we received approval from the Federal Aviation Administration (FAA) as an aircraft parts manufacturer.

- In 2023, we obtained NADCAP special process certification.

Core Values

In order to uphold the business philosophy of Gudeng and advance towards our mission and

vision, we strive to enhance Gudeng Precision's global competitiveness. Our founder

established our core values and principles of "Integrity and Honesty", "Excellence and

Innovation", "Proactive Accountability", "Win-Win Partnership", and "Team Collaboration". We

are committed to promoting the corporate culture of being a Partner with H.E.A.R.T.

(Heartfelt Service), and to Grow with P.A.S.S.I.ON. (Passionate Growth) within Gudeng

Precision.

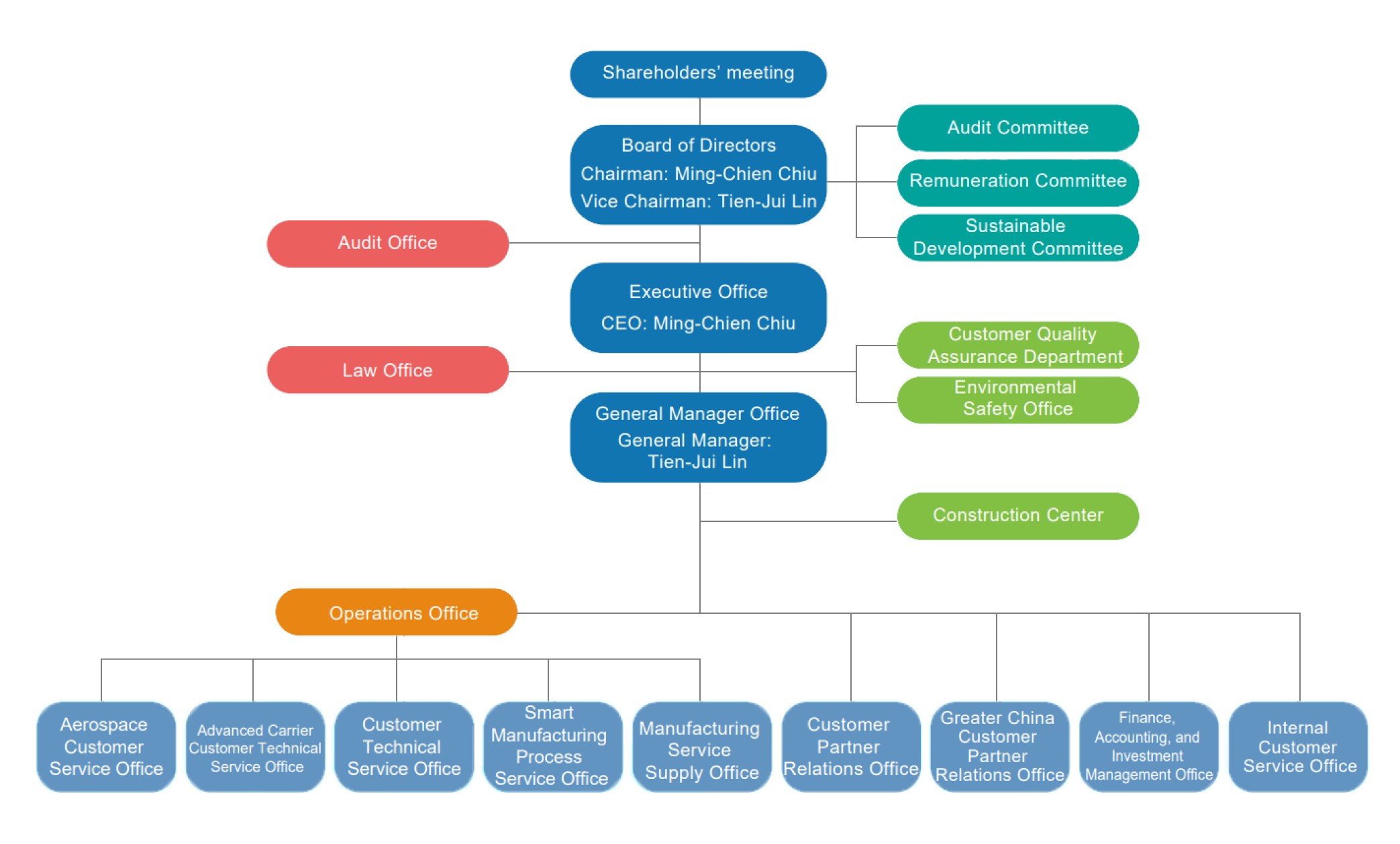

Organizational Chart

𝑷𝒓𝒐𝒗𝒊𝒅𝒊𝒏𝒈 𝒈𝒍𝒐𝒃𝒂𝒍𝒍𝒚 𝒄𝒓𝒊𝒕𝒊𝒄𝒂𝒍 𝒎𝒂𝒕𝒆𝒓𝒊𝒂𝒍𝒔 𝒂𝒏𝒅

𝒊𝒏𝒏𝒐𝒗𝒂𝒕𝒊𝒗𝒆 𝒕𝒆𝒄𝒉𝒏𝒐𝒍𝒐𝒈𝒊𝒆𝒔

𝑪𝒖𝒍𝒕𝒊𝒗𝒂𝒕𝒊𝒏𝒈 𝒈𝒍𝒐𝒃𝒂𝒍 𝒑𝒓𝒐𝒇𝒆𝒔𝒔𝒊𝒐𝒏𝒂𝒍𝒔 𝒊𝒏 𝒄𝒓𝒊𝒕𝒊𝒄𝒂𝒍

𝒎𝒂𝒕𝒆𝒓𝒊𝒂𝒍 𝒊𝒏𝒏𝒐𝒗𝒂𝒕𝒊𝒐𝒏 𝒕𝒆𝒄𝒉𝒏𝒐𝒍𝒐𝒈𝒚

𝑩𝒆𝒄𝒐𝒎𝒊𝒏𝒈 𝒕𝒉𝒆 𝒑𝒓𝒆𝒇𝒆𝒓𝒓𝒆𝒅 𝒑𝒂𝒓𝒕𝒏𝒆𝒓 𝒇𝒐𝒓 "𝒍𝒆𝒂𝒅𝒊𝒏𝒈

𝒈𝒍𝒐𝒃𝒂𝒍 𝒔𝒆𝒎𝒊𝒄𝒐𝒏𝒅𝒖𝒄𝒕𝒐𝒓 𝒄𝒐𝒎𝒑𝒂𝒏𝒊𝒆𝒔 𝒊𝒏 𝒄𝒓𝒊𝒕𝒊𝒄𝒂𝒍

𝒎𝒂𝒕𝒆𝒓𝒊𝒂𝒍𝒔 𝒂𝒏𝒅 𝒊𝒏𝒏𝒐𝒗𝒂𝒕𝒊𝒗𝒆 𝒕𝒆𝒄𝒉𝒏𝒐𝒍𝒐𝒈𝒚".

Sustainable Corporation - Continuous Innovation

Gudeng has invested decades of effort in the research and development of key products

such as our EUV POD and FOUP, achieving high market share and multiple growth in

production. We will continue to innovate technology and optimize system management

integration, providing customers with one-stop solutions for high-end photomasks and

wafer carriers. We also aim to diversify development into the aerospace industry, with

the group's goal of achieving annual revenue of billions in five years.

Sustainable Value - Creating Employment

We are expanding capital expenditures, establishing a new headquarters building in the

Tu Cheng Industrial Zone as a backup production base for photomasks, and beginning

construction of the Longfu factory in Sanxia District. Specialized product quality

control management, combined with automated system management, will reduce error costs,

improve yield, efficiency, and production capacity. With the goal of low-carbon

transformation and intelligent automated manufacturing plants, we plan to invest NT$5

billion locally over five years, creating 1,200 to 1,500 job opportunities to develop a

talent pool for the semiconductor industry in Taiwan.

Environmental Sustainability - Collaborating for Carbon Reduction

In 2022, the Gudeng-led upstream and downstream sustainable supply chain committee set a

2-year target for a 15% reduction in electricity consumption and a 3-year plan to

implement a digital carbon management platform. We are guiding 30 companies to take

actions for zero net emissions and carbon reduction through greenhouse gas inventory and

evaluation of the carbon footprint of key products, aiming to achieve our carbon

reduction target.

Leading by Example, Gudeng commits to and declares the implementation of RE100 by 2040

to supply renewable energy. The board of directors also approved investment in solar

power plants with energy storage equipment for direct power supply. We are striving to

achieve the target ahead of schedule by 2030, contributing to society with renewable

energy and dedicating our efforts to the sustainable development of the planet.

Since its establishment, Gudeng Precision has successfully developed end-to-end services from design to packaging, providing corresponding product solutions for semiconductor processes and enhancing customer service satisfaction.

Short, Medium, Long-term Goals

Sustainability Development Committee Structure

The first term of the Sustainability Development Committee appointed Mr. Chiu Ming-Chien as Chairman, Mr. Lin Tien-Jui as Vice Chairman, Mr. Chiu Kuang-Hui, Mr. Lo Wen-Hao, and Mr. Hu Hui-Sen as independent directors of the committee. Mr. Chiu Ming-Chien, Chairman, served as the convener, and the term is effective from the date of approval by the Board of Directors until July 29, 2024, coinciding with the current term of the Board of Directors. The Sustainability Development Committee has set up the Sustainability Office, with Director Zhu Hong-Bin appointed by the Board of Directors to integrate project members from the Financial and Investment Management Department, Information Security Committee, Supply Chain Center, Human Resources Center, Environmental Safety Office, and Customer Quality Assurance Department to establish and review related issues under the framework of the corporate sustainability response policy. Mr. Lai Po-An, Executive Officer of Corporate Governance, will act as the project manager to assist. The Sustainability Development Committee reports regularly to the Board of Directors and is subject to their supervision.

Achievements :

In 2022, the Sustainability Office compiled and published the Sustainability Report based on the sustainability strategy, short-term, medium-term, and long-term goals set by the Sustainability Committee. The company participated in the Corporate Sustainability Awards for the first time and was honored with the Gold Award in the Taiwan Corporate Sustainability Awards (TCSA) Sustainability Report category.

之肯定。Execution Status :

✓In 2022, the Sustainability Development Committee reviewed and approved the implementation plan for Gudeng's Intellectual Property Management, the greenhouse gas inventory and verification schedule, and the issuance of the 110th annual sustainability report. In the second half of the year, it also arranged regular discussions on the greenhouse gas inventory and verification schedule for consolidated subsidiaries' financial statements and reported to the Board of Directors.

✓ The company conducted a greenhouse gas inventory and announced our greenhouse gas emissions and reduction information on our public information website.